Central Cleaning System – CCS

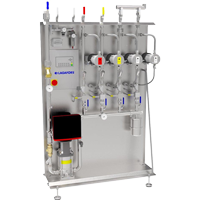

Variable Chemical Centre – VCC II

Variable Chemical Centre – VCC II

Provides central dosing of up to 12 different solutions and up to 50 simultaneous users.

Low Water Pressure pump – LWP

Low Water Pressure pump – LWP

Provides boosted pressure from 10-40 bar and up to 60 simultaneous users.

Hose Reel

Hose Reel

A hose reel keeps the hose organized and is usually mounted high to avoid contact with the floor, where contaminants are often present.

Satellite Station - VMS ll

Satellite Station - VMS ll

Hygienically designed satellite station for rinsing, foaming, and disinfecting, connected to any Lagafors Centralized Chemical unit.

Hose kit

Hose kit

Several types of food-grade hose kits, hose reels and accessories.

Central Cleaning System – CCS

By combining the components of CCS—which include the Variable Chemical Center (VCC II) and various types of water pump centers—customers can achieve cost savings of up to 35% compared to most existing cleaning systems and methods. These savings, along with the reduced environmental footprint, are the direct result of lower consumption of hot water, chemicals, and less wastewater.

The central components provide the right pressure, flow, and chemical concentration where needed, for up to 30 users simultaneously.

The pump center LWP (for water) and the chemical center VCC II are usually placed in a centrally located room. From there, pipes and lines run into the production area to the satellite stations. Each satellite station consists of a hose reel with hoses for water, chemicals, and disinfection. Centralized dosing and storage of chemicals enable safe handling and ensure no concentrated liquids are present in the production areas. Service, maintenance, and adjustments to the LWP and VCC II are carried out from the central location.

CCS is the only system that is fully LTS (Log Trace System) compatible.

%

Water savings up to

%

Chemical savings up to

%

Labor time savings up to

%

Increased personal safety up to

- Water pump center

- Chemical center VCC II

- Satellite station VMS II

- LTS compatible

- Flexible pressure and flow

- High dosing accuracy for chemicals/disinfectants

- User-friendly with hygienic design

- Logging, history, documentation

- Desired pressure and flow for up to 30 users simultaneously

- Optimized cost and environmental impact

- Efficient and hygienic in the production area

- Control over the cleaning process

Shaping the Future of Cleaning Equipment

We are committed to staying at the forefront of cleaning technology by hiring the best experts in the industry. Get in touch with us to be part of creating the cleaning solutions of tomorrow.