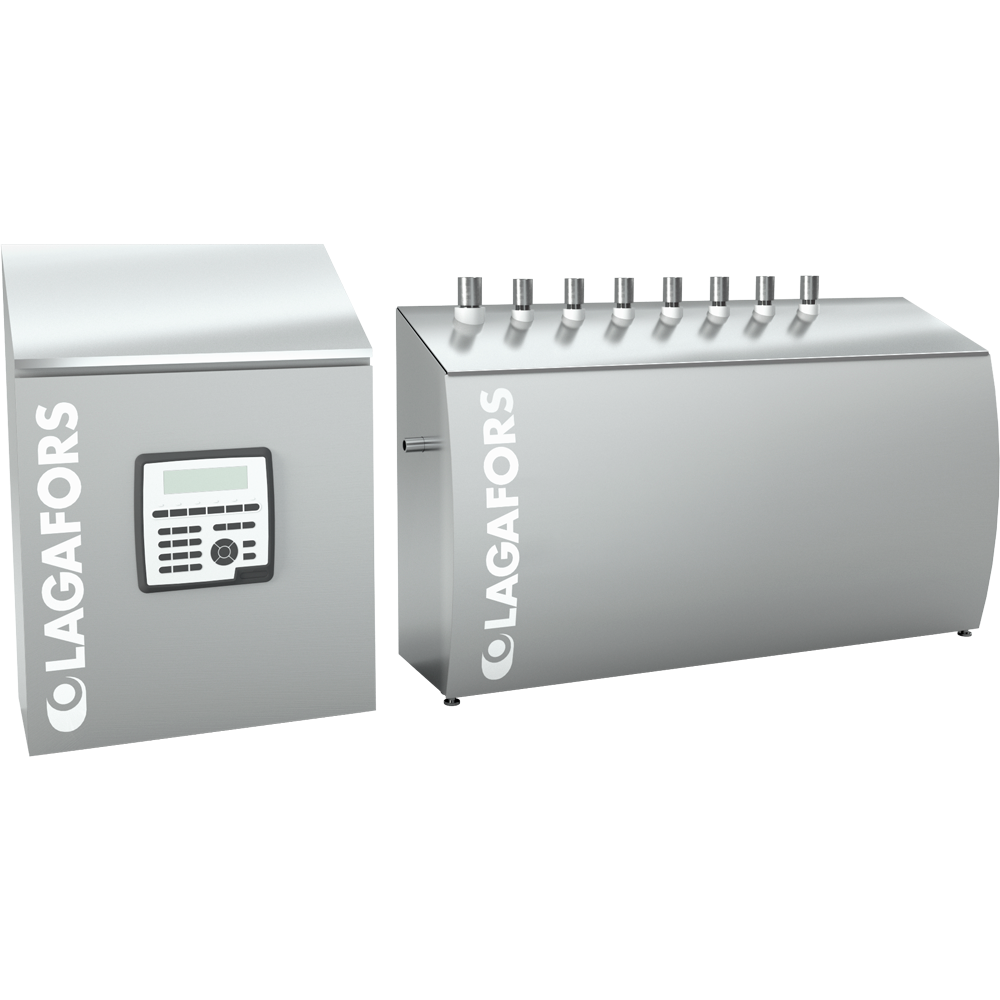

Automatic Cleaning System – ACS

Lagafors® Automatic Cleaning Systems, ACS II, consists of a control system and valve units for water, chemicals, and disinfection. The system is used to automatically clean all types of conveyor belts, elevator belts, conveyor tracks, and similar equipment. The design is based on Lagafors® well-known satellite station series VMS II and is hygienically adapted for the food industry. The ACS system is developed to be connected to any of Lagafors’ pressure water units and the dosing center VCC II for chemicals and disinfection.

The unit is user-friendly, easy to maintain, and clean. The system provides the customer with continuity in cleaning, improved hygienic results, significant time savings, and reduced consumption of water, chemicals, and disinfection.

The ACS system can advantageously be connected to control Lagafors’ Washing Ramps SSB (page 46). External control of the valve stations is also possible.

The ACS unit consists of:

- Stainless steel control cabinet with Siemens PLC and touch display

- Stainless steel valve cabinet with rotary actuator for water

- Stainless steel valve cabinet (Combi) with rotary actuator for water, chemicals, and disinfection

Water saving up to 50%

Chemical saving up to 50%

Labor time saving up to 75%

Increased personnel safety up to 75%

- Time-efficient

- Easy to clean

- Washes, foams, disinfects

- Time saving

- Minimal staffing required

- Time-efficient

- Easy to clean

- Washes, foams, disinfects

- Time saving

- Minimal staff requirements

- Low installation cost

- Good from a hygiene perspective

- Good and even cleaning results

- Lower media consumption

- Saves a lot of labor time

Shaping the Future of Cleaning Equipment

We are committed to staying at the forefront of cleaning technology by hiring the best experts in the industry. Get in touch with us to be part of creating the cleaning solutions of tomorrow.