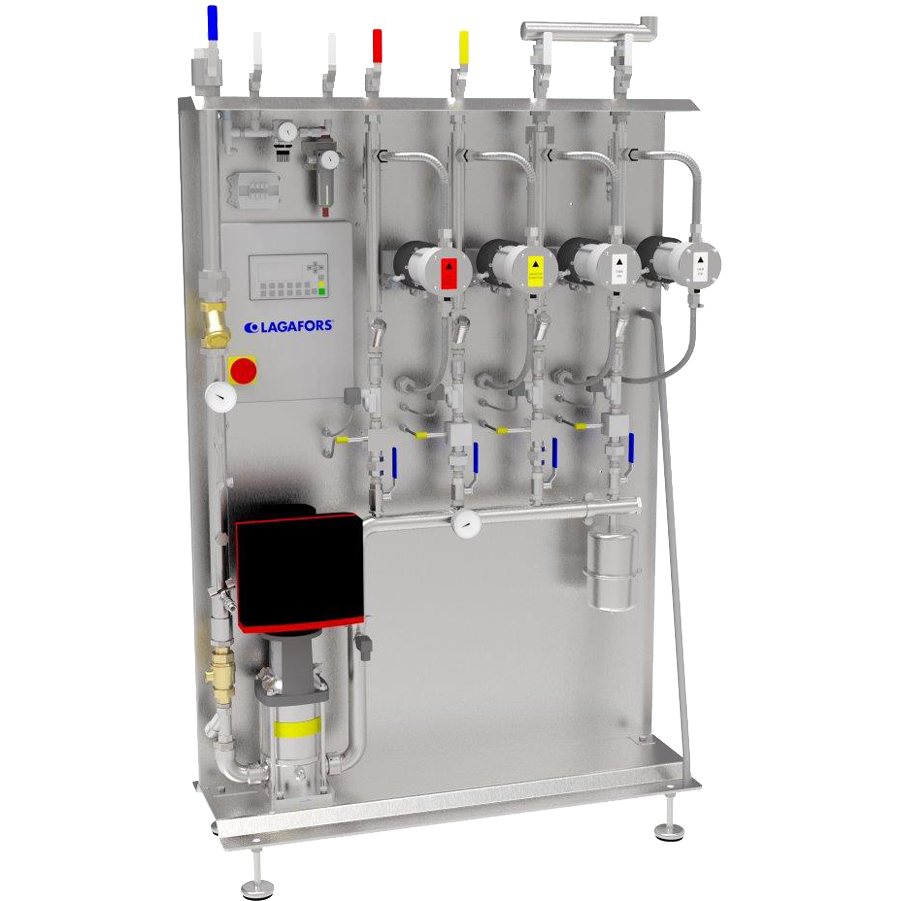

Variable Chemical Centre – VCC II

Lagafors® unique centralised chemical dosing system VCC, Variable Chemical Centre, now has a newly developed successor in the VCC II. The focus has been on increased capacity, flexibility, improved material selection and components, as well as enhanced user safety. It also offers much more efficient maintenance and technical service.

The unit consists of a booster pump, 1–12 chemical dosing modules, and a control unit. The dosing precision of ±0.1% in the working solution ensures optimal chemical concentration with maximum results. Up to twelve different chemical solutions can be dosed and used simultaneously.

Over the years, the VCC has proven especially suitable in environments where high hygiene standards and optimised resource usage are desired – such as slaughterhouses, dairies, breweries, fish processing plants, the meat industry, ready-meal production, and large-scale kitchens.

Model VCC II/70: Capacity 1–12 simultaneous users (6–70 liters/min / 1.3–15.4 UK gal/min)

Model VCC II/140: Capacity 1–24 simultaneous users (6–140 liters/min / 1.3–30.8 UK gal/min)

Model VCC II XL 140/280: Capacity 1-48 simultaneous users (6–280 liters/min / 11.3–62 UK gal/min)

- Main components: booster pump, 1–12 chemical dosing modules, and PLC Siemens S7-1200

- LTS compatible, giving the customer full control over their cleaning process

- High dosing accuracy (±0.1%) ensures low chemical consumption

- Flexible, handles various combinations of up to twelve chemicals

- Level sensor with alarm is standard

- Dosing range 1–6% standard. Low dosing 0.005–0.5% available on request

Chemical savings up to 35%

Labour time savings up to 50%

Increased user safety up to 90%

- High dosing accuracy (+/- 0.1%)

- Constant chemical concentration

- Centralized storage of chemicals

- Centralized dosing

- Separate water systems

- Reduced environmental impact

- No variations in concentration

- No chemical concentrates in the production area, less handling of concentrates

- Bulk purchasing of chemicals

- Ability to set the desired temperature of the diluted chemical solution

- Lower chemical costs

- Reduced chemical consumption

- Reduced risk of chemical accidents, no waste issues with chemical containers

- Lower cost per liter of chemical, time savings during changeover

- Optimal chemical efficiency, improved working environment, reduced amount of aerosols

Shaping the Future of Cleaning Equipment

We are committed to staying at the forefront of cleaning technology by hiring the best experts in the industry. Get in touch with us to be part of creating the cleaning solutions of tomorrow.